Wholesale Electric Tricycle Manufacturer In China

Zaoyeo is a new brand specializing in new energy electric tricycles , backed by over 10 years of experience in manufacturing electric tricycles and three wheeler e-trike. We produce a wide range of models including cargo tricycles, passenger 3 wheels vehicle, and compact electric utility vehicles.

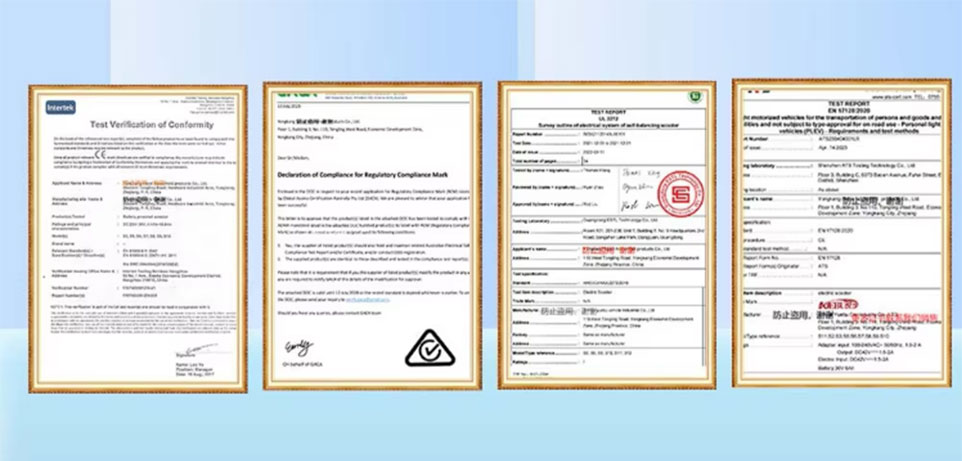

All of our products meet international quality standards and have been successfully distributed across various global markets. We also offer customized solutions to meet different transportation and business needs.

We are actively seeking partnerships with regional agents and distributors worldwide. With years of experience in international trade, we have served numerous global clients and understand the importance of timely delivery and customer satisfaction.

At Zaoyeo, we value customer service and provide reliable door-to-door shipping to most countries. Our professional support and fast production turnaround ensure a smooth and efficient experience for our partners.

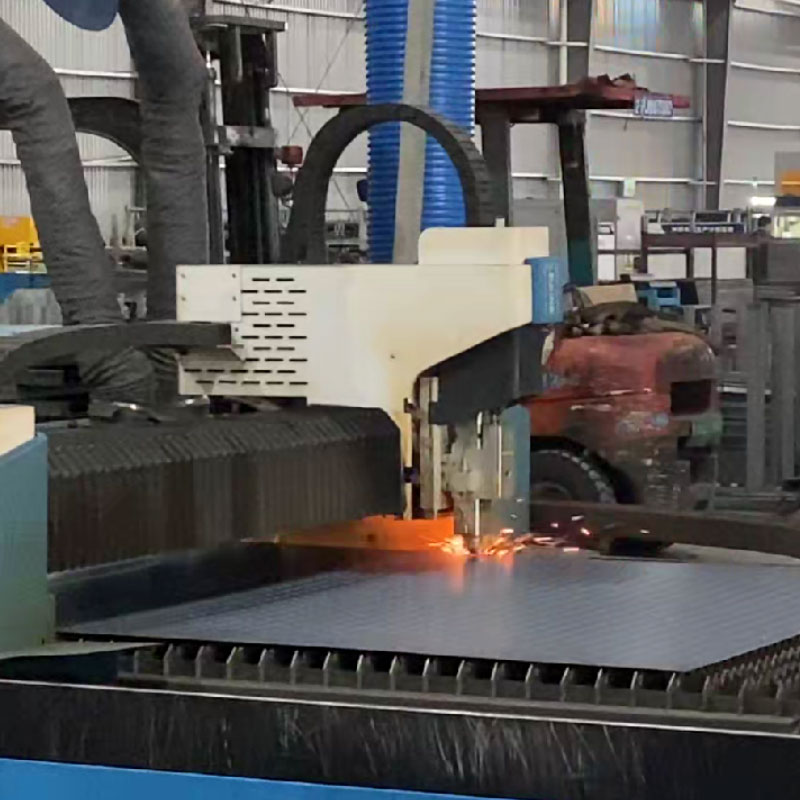

Step 01

Material Cutting

Precision stamping of steel frames,essential for electric cargo trike structure and durability.

Step 02

Welding

Automated welding for electric tricycle frames ensures consistent strength and quality across units.

Step 03

Paint Application

Triple-layer spray and bake coating process

Step 04

Component Assembly

Expert assembly of electric motors,batteries,and conttrollers onto tricycle frames for optimal performance.

Step 05

Quality Testing

Rigorous testing,including electric cargo trike load capacity and electronics functionality for reliability.

Step 06

Perfomance Tunning

Final adjustments to ensure electric cargo trike handing and efficiency meet high standards.

FAQ